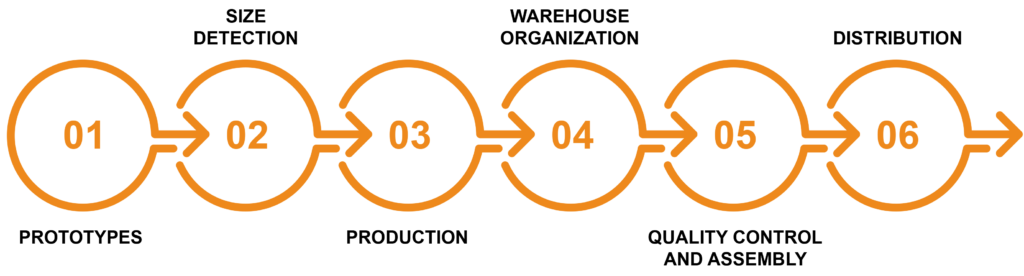

PRODUCTIVE PROCESS

PROTOTYPES

Research, to create products that are the representation of your company and of the Your territory. The study of raw materials, to meet the technical and qualitative needs of your sector with materials suitable for your activities employees.

Behind an Uniform in our headquarters there is a design team who create and develop great projects to assure the highest results to our costumers.

SIZE DETECTION

Request list by separate categories (Captains, Pilots, Cabin Crew, Ground Staff …), sex and identification number.

Appointment of a company’s internal reference with whom to exchange information about the staff and its availability.

Organizational performance and logistics of two EGV1 members to transfer to the staff of the customer our know how in order to correctly manage the distribution. This stage usually lasts 30 days or upon customer request.

PRODUCTION

Production of the uniform items as agreed starts from the whole detection of the staff’s sizes and confirmation of each sample produced from the modeling of creative proposals.

Time of production will be considered of 90 working days including research of row material.

WERAHOUSE ORGANIZATION

Identification of a space appropriate to the needs located near the headquarters of the airline to make easy the service of management of uniform, for which an appropriate square footage will be identified with the volumes of the goods to be handled.

Setting up the space through shelving in observance of the vertical development, stender, dressing rooms for the fitting tests delimited by mirrors separators, and other consumables in in addition to handling equipment such as forklift truck.

Implementation of computerized support for the nominative management of distributions with emission of identification cards for the assignment of the size worn

QUALITY CONTROL AND ASSEMBLY

All components should be sent from the factory to our warehouse in Gallarate (ITALY) where we will perform quality control.

The uniform will be subsequently assembled in all its parts and in a nominal box.

Issuance of a list where it will be shown each item assigned to each employee . This list will be forwarded to the contact person of the company.

All packages are correctly prepared for shipment

DISTRIBUTION

Uniform testing with the release of a signed statement confirming the withdrawal.

Tailoring adjustments where necessary with the support of suitable local staff.

Duration of distribution will be performed within 30 days with the presence of our staff who will support company’s team.

“READY TO FLY”

Staff will be trained to correctly wear the uniforms.

Planning of reinstatements on agreed basis.